Welcome from the Editor-in-Chief

The ASME Journal of Mechanical Design (JMD) serves the broad design community as a venue for scholarly, archival research on all aspects of the engineering design activity. JMD has traditionally served the ASME Design Engineering Division and its technical committees, but it welcomes contributions from all areas of design with an emphasis on design synthesis.

The ASME Journal of Mechanical Design (JMD) serves the broad design community as a venue for scholarly, archival research on all aspects of the engineering design activity. JMD has traditionally served the ASME Design Engineering Division and its technical committees, but it welcomes contributions from all areas of design with an emphasis on design synthesis.

Designing Together: Exploring Collaborative Dynamics of Multi-Objective Design Problems in Virtual Environments

SPECIAL ISSUES Call for Papers

Call For Papers: Special Issue on Design and Synthesis of Remote Center of Motion Mechanisms

Robotic manipulators capable of generating a Remote Center of Motion (RCM) enable a device, instrument, or tool to rotate around a fixed point that is

WEBINARS

The Journal of Mechanical Design Webinar Series is a series of webinars organized quarterly to feature interesting research work being published in the Journal of Mechanical Design (JMD).

Webinar 1

DATA-DRIVEN APPROACHES FOR ENGINEERING DESIGN

Webinar 2

TEAM SCIENCE IN ENGINEERING DESIGN

Webinar 3

DESIGN FOR ADDITIVE MANUFACTURING

Webinar 4

ROBOT DESIGN

Webinar 5

DESIGN ENGINEERING IN THE AGE OF INDUSTRY 4.0

Webinar 6

ARTIFICIAL INTELLIGENCE IN ENGINEERING DESIGN

Webinar 7

INTEGRATED DESIGN AND OPERATION OF ENGINEERING SYSTEMS WITH PREDICTIVE MODELING

Webinar 8

CO-DESIGN OF ROBOTIC SYSTEMS

Webinar 9

EMERGING TECHNOLOGIES AND METHODS FOR EARLY-STAGE PRODUCT DESIGN AND DEVELOPMENT

Webinar 10

TOPOLOGY OPTIMIZATION

Webinar 11

ADVANCES IN DESIGN AND MANUFACTURING FOR SUSTAINABILITY

Webinar 12

Design of Materials and Structures

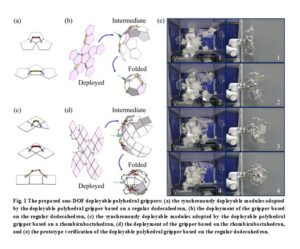

Structural Designs of Novel Deployable Polyhedral Grippers for Noncontact Capturing Missions

Read More »EDITORIALS

The editorial board of the Journal of Mechanical Design (JMD) endorses the commitment of ASME to support diversity and to create and ensure inclusive and ethical practices for publishing as well as the science and engineering professions. Over the past few years, JMD has continuously expanded the geographic and gender diversity of its editorial board, with close to 30% of its editorial board being women or from underrepresented groups. JMD has championed and implemented the double-blind review option to promote objectivity in the review process and reduce bias based on the authors’ country, gender, and seniority. In addition, JMD has reached out to underrepresented groups, young researchers, and women to feature as JMD webinar organizers and speakers. For suggestions to further improve the journal’s DEI practices, please contact JMD’s DEI advocate, Scott Ferguson at smfergu2@ncsu.edu.

ABOUT JMD

ASME Journal of Mechanical Design (JMD)

Publishing Frequency: Monthly

2022 Impact Factor: 3.300

2022 Five-Year Impact Factor: 3.800

Representative Topics

- Design automation, including design representation, virtual reality, geometric design, design evaluation, design optimization, data-driven design, artificial intelligence in design, simulation-based design under uncertainty, design of complex systems, design of engineered materials systems, shape and topology optimization, engineering for global development, ergonomic and aesthetic considerations, and design for market systems;

- Design of direct contact systems, including cams, gears and power transmission systems;

- Design education;

- Design of energy, fluid, and power handling systems;

- Design innovation and devices, including design of smart products and materials;

- Design for manufacturing and the life cycle, including design for the environment, DFX, and sustainable design;

- Design of mechanisms and robotic systems, including design of macro-, micro- and nano-scaled mechanical systems, machine component, and machine system design;

- Design theory and methodology, including creativity in design, decision analysis, preference modeling, user-centered design, design cognition, entrepreneurship and teams in design, design prototyping, and design synthesis.